There is a changing perspective on how fashion is being conceived and how the fashion industry can reap the benefits from advancing technologies to achieve more efficient and productive business practices. The need for adopting a 3D fashion design platform is becoming more prevalent within the industry as digital design and 3D assets are gradually becoming the key technologies within the fashion supply chain.

Whether you are in the process of making the shift to digital or debating whether 3D is the way to go, we’ve narrowed down the five benefits of utilizing a 3D design software for your apparel workflow that will enable you to:

1. Save Time

Traditionally, the sampling process can add up to 4-6 weeks to your apparel calendar. The back-and-forth communication between the designer and the manufacturer has proven to be complex due to different time zones and the time and costs accumulated for producing physical samples.

3D bridges this gap as decision-makers can now communicate globally with internal and external stakeholders by simply sharing the 3D garment across all locations online. As a result, stakeholders can collaborate on changes and alterations to a digital prototype and perfect the products in a matter of minutes before sewing a single seam.

2. Improve Product Quality

Greater collaboration results in faster decision-making, ultimately leading to higher quality products. With Browzwear’s 3D fashion design software VStitcher’s true-to-life 3D capabilities, designers can present their designs in all different colors, sizes, and styles, eliminating the majority of the associated costs and not to mention, time delays.

By the time the first physical sample is produced, the stakeholder approval rate is much higher, with all changes being made digitally before being sent to production, improving the quality of your garments and ensuring the perfect fit.

3. Achieve a Faster Time to Market

Save significant product development time and remove the bottleneck of creating and showcasing physical samples. With 3D, fashion designers and leading apparel brands like Puma and Superdry are now better streamlining their processes and making confident decisions when validating their garments’ fit and styling. Leveraging a digital twin of the physical garment leaves no room for uncertainty, significantly accelerating the time to market.

Save significant product development time and remove the bottleneck of creating and showcasing physical samples. With 3D, fashion designers and leading apparel brands like Puma and Superdry are now better streamlining their processes and making confident decisions when validating their garments’ fit and styling. Leveraging a digital twin of the physical garment leaves no room for uncertainty, significantly accelerating the time to market.

By spending less time creating a physical sample, designers can now focus on getting things done right the first time around, faster and more efficiently.

4. Visualize the Final Product

With hyper-realistic garment visualization offered by Browzwear’s VStitcher, designers to see what the final product will look like and capture any pattern faults or imperfections that may have appeared on the physical garment without producing a single physical sample.

Browzwear’s Fabric Analyzer enables designers to see the physical properties of a digital prototype, from the fabric’s thickness and stretch to the texture and how the fabric folds and falls on a real human body. These capabilities ensure that the outcome of the garment is accurate and requires minimal revisions.

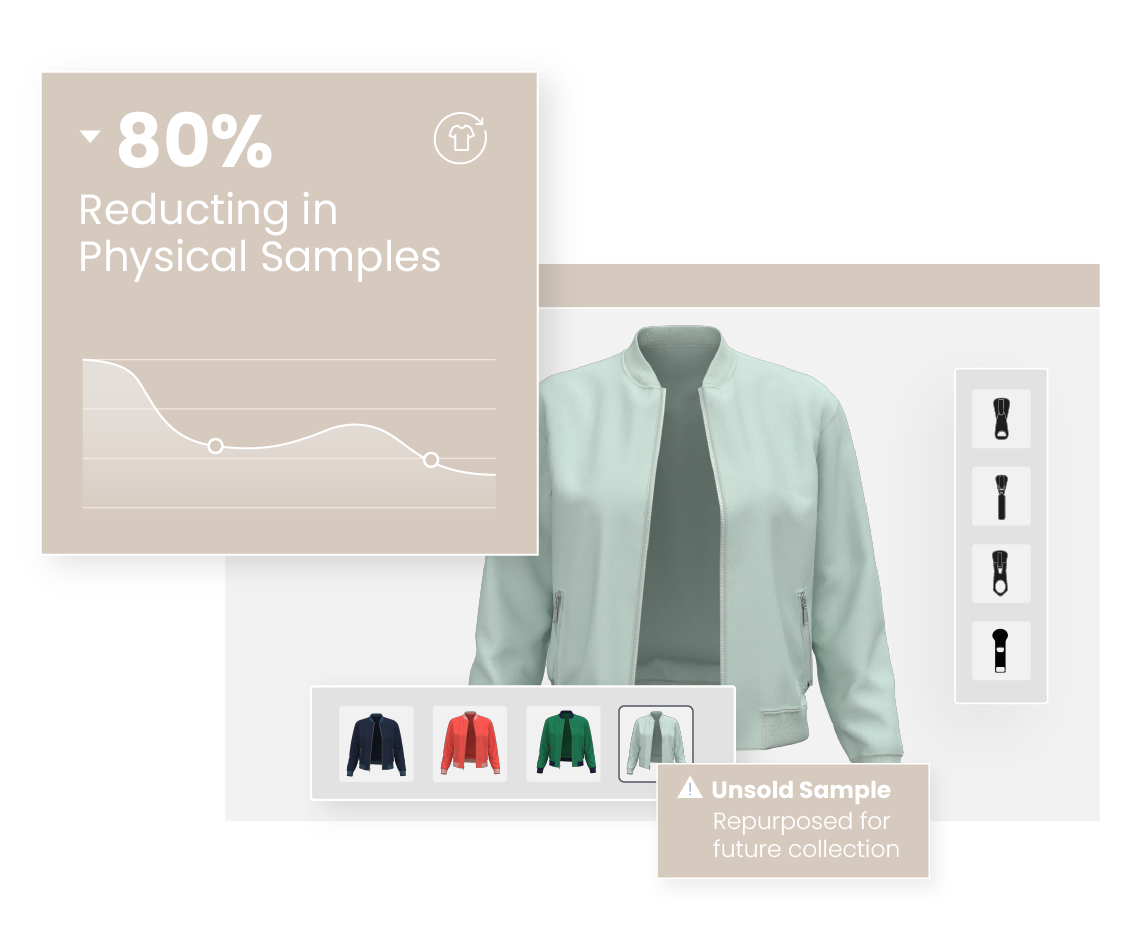

5. Reduce Your Environmental Footprint

As the world moves towards greener and more sustainable outcomes, 3D technology enables apparel organizations to execute their entire digital sampling process without committing to fabrics, saving up to 80% of fabric waste. Doing so saves time and costs and enables your organization to replace physical samples, which traditionally would be thrown away in landfills, with true-to-life digital twins.

As the world moves towards greener and more sustainable outcomes, 3D technology enables apparel organizations to execute their entire digital sampling process without committing to fabrics, saving up to 80% of fabric waste. Doing so saves time and costs and enables your organization to replace physical samples, which traditionally would be thrown away in landfills, with true-to-life digital twins.

By utilizing Browzwear’s Sustainability Calculator , you can determine the amount of carbon dioxide you can reduce and the water you can save by developing styles in 3D.

If you’re ready to explore the world of 3D fashion design and achieve your creative potential, schedule a demo to see Browzwear’s 3D fashion design software in action.