Sean Lane’s 3D Tech Festival Session Overview

By shifting to digital, apparel organizations can conduct these processes with speed, quality, consistency, and connectivity.

October 31, 2022

Now or Never:

The dynamics of the fashion industry are constantly evolving; an industry that has traditionally veered away from technology has begun to embrace it at an accelerated rate. As recent global events have led the apparel workforce to gradually become more remote, digital tools play an increasingly vital role for apparel brands in a post-pandemic era. 2021 alone saw apparel organizations invest between 1.6. and 1.8 percent of their revenues in digital technology.

The apparel industry was one of the worst hit by the COVID-19 pandemic. All sectors of the fashion world, from brands to manufacturers and fabric mills, have faced new challenges, giving the industry little to no choice but to adopt digital alternatives to physical processes to remain competitive.

In light of the pandemic and its continuous impact, apparel brands of all specialties have found themselves in a position where they cannot operate as they have in the past. It is increasingly challenging to receive physical samples from suppliers within a reasonable time, making it even more difficult for stakeholders to approve new season design cycles in line with the market release time.

However, these challenges have also highlighted existing issues in the system and apparel organizations are now focusing on strengthening their digital transformation strategies to be prepared for future challenges. It is expected that by 2030, apparel companies will double their investment in technology to keep their competitive edge.

As with any transformation process, change must be adopted from an organization’s core to be effective and sustainable. It’s not as simple as downloading 3D clothing design software, apparel companies must undergo an end-to-end transformation, embedding a digital culture throughout the entire organization, from the stakeholder to the consumer level.

For a successful digital transformation, it is crucial to have a cohesive collaboration between all stakeholders. Each member plays a vital role, in conjunction with the processes and technology. Additionally, companies must possess the necessary tools and readiness to establish the foundation for digital integration.

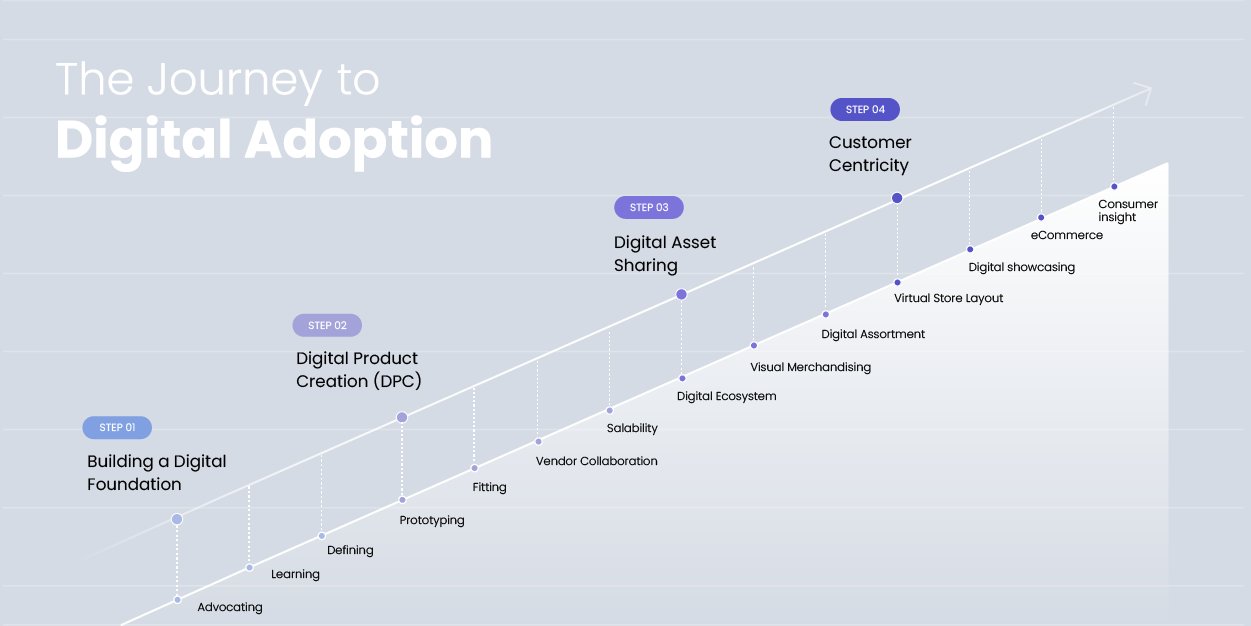

To begin with, companies should establish the necessary infrastructure for 3D implementation and invest in developing a digitally skilled workforce. Once the teams are identified and their proficiency is assessed, a framework can be created for effective digital product development. At this point, the organization can then expand by utilizing digital asset sharing and applying it to customer-facing operations.

When looking at digitally transforming your apparel business, remember it’s a marathon, not a sprint!

Pillar 1

Pillar 1 When gearing up your organization for digitization, the right infrastructure must be built to establish a solid base prepared for 3D adoption. Which means:

Advocating – The process of designing apparel using 3D technology can be challenging. Not all employees may be receptive to change or willing to adopt new technologies. Therefore, identifying the team members who will support you throughout the journey is crucial. In the long run, this will allow you to better understand and address internal obstacles, and to use the support to overcome resistance within the organization. This team will also grow and share their knowledge of best practices and techniques to help others adapt to the changes.

Learning – To effectively onboard employees to 3D technology, professional training and easily accessible learning resources are required to develop a workforce proficient in digital skills. Prior to beginning, a comprehensive training program should be established, where individuals can acquire the necessary skills, which will be essential for them to adapt to the change. It is important to provide your team with an accessible and user-friendly learning source, such as Browzwear University, where they can acquire the essential tools and skills needed to become proficient users of Browzwear’s 3D clothing design software, VStitcher . When more employees have successfully adopted 3D and have reached a certain level of proficiency, it is essential to identify the teams that will work with digital tools to ensure alignment, in order to establish efficient and seamless workflows.

Defining – It is important to take the time to document all the systems that will be involved in and integrate with the digital workflow. These systems should be connected and libraries should be established as the foundation of the 3D work, including digital fabrics, trims, prints, S/N, and more. Collaborating with internal teams and vendors will facilitate standardization, which will be beneficial for both short-term and long-term onboarding.

Pillar 2

Pillar 2 Once a digital infrastructure has been established, the Digital Production Creation process can be carried out gradually, with Browzwear’s fashion design software at the core. Yet this process is complex, requiring cooperation between each of the stakeholders of the product, from design teams to vendors, while maintaining a collaborative environment. Therefore, as changes and adaptations are made, all members can be kept aligned throughout the process. Rather than being a siloed process based on a single technology, DPC requires cross-functional collaboration and integration, covering aspects including:

Prototyping – Shifting from a traditional physical prototype to a 3D apparel digital twin is not an easy process, and trust must be established by both the creators and the validators that what is seen on the screen will bring the same outcome from the manufacturer.

Fitting – The first step to achieving accuracy is by validating the sizing and technical fit of the garment, ensuring that each physical property of the garment and how the materials behave and interact when worn on the body.

Vendor Collaboration – Another way to ensure accuracy and consistency from DPC through to production is by enabling the vendors and manufacturers to participate in the process and understand the 3D garment they will receive. Reading the details, knowing the internal VQS, and proactively working on the garment before production is key to receiving a physical twin.

Sellability – At this stage of the creation process, digital tools promote a cost-saving approach and prevent errors and waste from occurring further down the line. One essential tool is Voice of Customer, which enables brands to manufacture the sellable to avoid garment write-offs. When you gain consumer knowledge and insights at the pre-production stage, future collections can be prepared and adjusted accordingly. This works to hasten time to market by selling sellable products only and minimizing future costs.

Having a well-functioning DPC stage enables the organization to run the rest of the digital transformation process. If this process is accurate, then it will achieve the following:

Once the DPC process has been defined, all foundations are set in place, so you can begin scaling the technology across your organization. Now’s when it’s time to think about managing all of the digital assets for selling throughout the B2B pipeline. One of the most significant differences between digitally transformed companies and those that have kept the traditional model is digital asset sharing. This most often consists of the following:

Digital Ecosystem- By utilizing Browzwear’s Open Platform , companies can access a constantly expanding ecosystem of pre-integrated partners and services to integrate their in-house software and processes. By utilizing a variety of technology solutions, apparel companies can harness the power of 3D throughout the design, production, and sales process.

Visual Merchandising – By having a digital twin assortment that accurately represents the physical collection, retailers can roll out the 3D store simulation faster and with a high level of precision.

Digital Assortment- Apparel brands can only prepare seasonal collections using digital garments. This enables retailers, wholesalers, and manufacturers to plan and ensure they meet customer demands before physically producing the pieces.

Virtual Store Layout- With digital assets, the internal pitching process can be carried out virtually using digital, photorealistic showrooms and interactive catalogs. This facilitates the development of an end-to-end digital workflow covering each aspect of the supply chain and product lifecycle from the design to the consumer level.

Pillar 4

Pillar 4 As proficiency in digital technology increases throughout the company, and it becomes integrated into production and business operations, the company can expand into customer-facing areas. While this expansion can occur earlier, having a strong foundation in place allows for a seamless and more efficient process.

Digital selling on the consumer front includes:

Digital showcasing – Allows the selling process to be conducted with digital garments only, and buyers can enjoy an immersive and interactive online shopping experience. Tools such as digital catalogs offer brands a virtual alternative to in-person meetings. Moving to a virtual showroom significantly reduces the cost of physical sample production and facilitates risk mitigation. Pricing can also be aligned across the board, eliminating cost uncertainty.

Interactive tools for eCommerce – Interactive tools can showcase digital garments across eCommerce platforms. For example, 3D product configurators allow users to maneuver the garment and view it from different angles to achieve their desired result.

Additionally, other tools that work to combine a personal avatar with a made-to-measure garment create the ultimate personalized shopping experience. It’s solutions like these that untimely boost buyer confidence in online shopping.

Consumer insights – Utilizing sales data to understand and analyze the market’s behavior and have the ability to make informed decisions before releasing a collection. The information obtained can be used to improve or modify garments in 3D to optimize the collections, speed time to market, and significantly save on production costs.

It is important to note that there is no universal approach or single technology that can be used for large-scale digital transformation. An organization must go through multiple stages of transition to establish a new digital culture and implement core processes. Once a strong foundation is in place, it can be further developed and tailored to the organization’s specific needs, covering everything from the organizational structure to technology and customer needs

If you are considering starting a digital transformation journey, our business solutions team is available to guide you through the process. This includes evaluating your current organizational structure and readiness for digital adoption, as well as identifying the tools and strategies needed to provide a comprehensive solution that fits your unique needs.

By shifting to digital, apparel organizations can conduct these processes with speed, quality, consistency, and connectivity.

Mastering creativity and technical skills in apparel organizations undergoing digital transformation

This professional hub has been created for organizations that utilize Browzwear’s 3D fashion design software within their daily operations.