The way fabric pieces are cut in relation to the fabric grain line has a big impact on the way a garment looks. While you’re designing or making the pattern using 3D software, you should be able to see the effect accurately in the 3D simulated garment.

For example, take this long T-shirt. The bias-cut drapes softly. The straight-cut is stiffer, and there are fewer folds in the fabric.

What is the Grain Line?

The grain line is the direction of the weave in which the thread runs the entire length of the fabric and is parallel to the salvage. For fashion designers and pattern makers, it refers to the way a pattern is cut when it’s laid out on the fabric, which affects the way the final garment stretches and drapes.

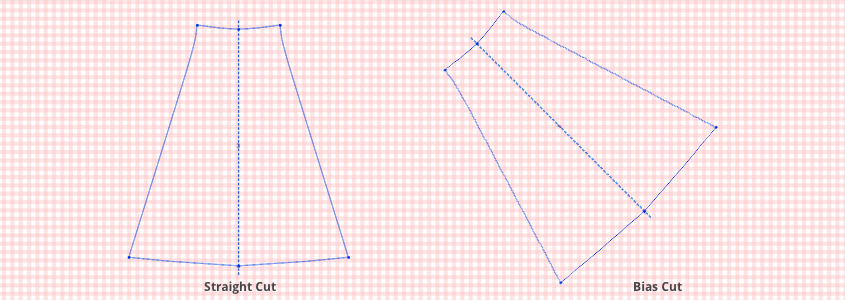

When a “straight cut” is used, that means the grain line is parallel to the vertical thread (the warp) of the fabric. This is the most common placement.

In the “bias cut”, the piece is cut 45 degrees in relation to the vertical thread in the fabric. The bias cut is most often used in evening wear, bridal gowns, couture and other high-end garments. Bias-cut garments have a softer look with more ripples.

True-to-Life 3D Grain Line Simulation

Since the bias-cut is typically more costly, it’s important to visualize the effect and evaluate the benefits before manufacturing. With true-to-life 3D, that’s possible. Here you see the same dress, with the same fabric on the same model – once straight cut, and once cut on the bias. With vSticher, it’s simply a matter of indicating on the pattern how the fabric should be cut.

Straight Cut

Bias Cut