Kohl’s Kelley White on Adopting Browzwear with 3 Simple Tactics – Browzwear Night at FIT 2023

Kohl’s is a leading Omni Channel retailer with over 1,100 locations across the United States.

April 15, 2021

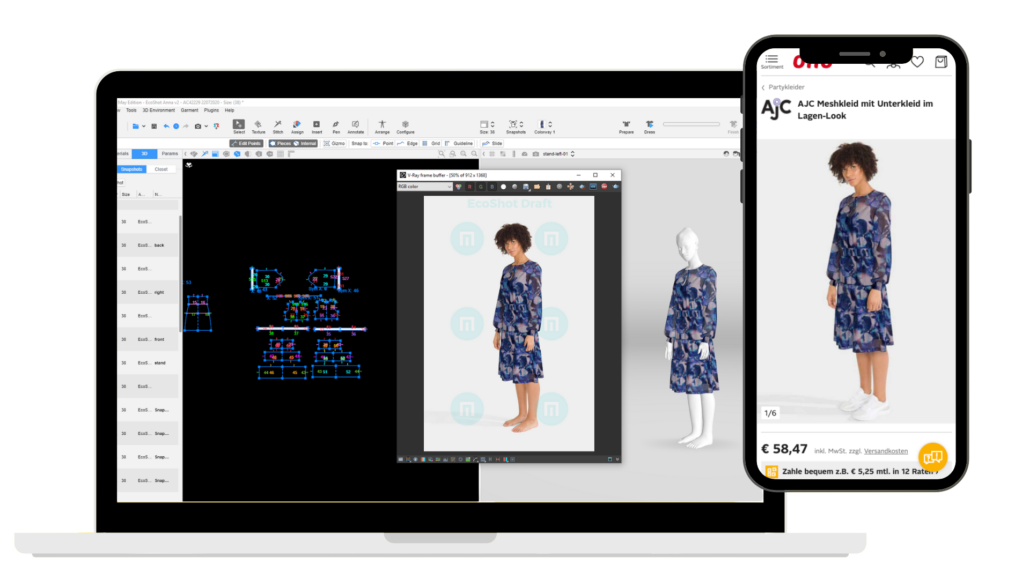

As the virtual development competence center of Otto International (OI), Featuring LIMITED provides fully customized 3D digital product development services. Featuring LIMITED’s transition to digital solutions is a crucial part of Otto International’s digital transformation. OI, a member of the Otto Group, offers solutions at every step of the sourcing process and has incorporated a wide array of third-party and in-house digital programs into its everyday operations, from virtual design, to quality inspections, to shipping. This drive to digitization links to the desire to conduct business in the most sustainable way possible. The team at Featuring is committed to innovation, focusing on the implementation of 3D design solutions from the early stages of product development through to production, minimizing sample lead time, reducing inventory waste, and fulfilling their sustainability objectives. From 3D footwear to apparel, Featuring LIMITED embraces the latest technology to bring their customers agility and speed through a fully digitized and customized product development process, catered to their unique needs.

Before 3D adoption, Featuring LIMITED worked with multiple vendors and customers throughout the sampling process, which often saw both costly and time-consuming approval processes when it came to the design and fit of each garment. This involved shipping physical samples back and forth between vendors and customers located across Asia and Europe before they could be finalized. As a result, the company saw that a significant part of the cycle was being wasted on downtime between sending out the samples and receiving feedback. The company was eager to overturn the traditional product development process to reduce overall costs and boost business efficiency. Thus, Featuring LIMITED teamed up with Browzwear in 2017 to overcome these challenges and welcome a new, digital solution the company believes to be the next natural step for the industry.

The technical team at Featuring LIMITED began their 3D journey with Browzwear by recreating physical samples in digital form and examining the differences until they were able to achieve the digital twin of the physical sample.

“As the technical team began creating more and more true-to-life garment simulations, it was incredible to see just how close the 3D and physical worlds are, and the results spoke for themselves,” says Katharina Bobrowski, GM, Featuring LIMITED.

As the team became more familiar with Browzwear’s 3D design software, VStitcher, their priority was shifting the fit validation process to a digital workflow to eliminate the traditional dependency on real-life models and physical prototyping. Not only would 3D enable the company to cut back on physical resources, but it would also greatly impact the time spent on identifying and implementing design changes. “You can cut down unnecessary samples and cut down the transit time of sending physical samples from location A to B,” says Katharina. She further explains that once designers can have size fittings based on real measurements and accurate materials at hand before a collection is sent to production, stakeholders can leverage 3D to make more informed decisions based on the product’s digital twin, ahead of time.

As featuring LIMITED is situated in Asia, with the majority of its clients spread across Europe, 3D implementation soon enabled the Otto International QA team to execute the fit approval process entirely digitally, allowing any potential design faults or fit issues to be resolved before being physically produced. “Utilizing VStitcher’s virtual garments that are true-to-life gives the decision-makers the confidence to depend on the fact that each aspect from the seams and trims through to the garment drapes on the body, will be identical to the physical. Therefore, we can omit any potential errors that may occur further down the line, and adjustments can be made and re-approved within minutes,” says Katharina.

After experiencing the initial successes that 3D brought to the table, the team was ready to take things up a notch. “You can use 3D internally to improve efficiency, speed up the development process, but of course, if you wish, you can apply it to every single aspect of the supply chain and reach out to the consumer,” she adds. When working with customers, they began to incorporate their feedback into the product development process, as a way to evaluate the garments with the consumer before launching a collection. “We can create a digital garment and test it on the consumer, before using up any physical resources,” Therefore, apparel brands can now cater their collections according to their market, prudence garments that are assured of a good sell-through, and lower the risk of garment deadstock and inventory waste.

The pandemic has had sweeping effects on the fashion industry and has presented apparel companies with an entirely new set of obstacles. With limited access to physical samples and the inability to conduct in-person meetings, both brands and manufacturers have found themselves in situations where they have come to a standstill when it comes to selling. During these unsettling times, some of Featuring LIMITED’s customers ran into difficulties when it came to maintaining marketing timelines between the Far East and Europe. “The technology helped us to create accurate samples, which meant that companies were still able to keep up with the marketing schedule, still present the garments, and not lose out,” says Katharina. Throughout the pandemic, 3D has been able to assist companies at different levels of digital maturity. For example, giving wholesalers that are typically reliant on trade shows for selling, the ability to showcase their pieces virtually on human photography using innovative tools such as Metail’s EcoShot .

Since implementing Browzwear’s solution, Featuring LIMITED provides its clients with an accelerated and more efficient product development process, with fewer physical samples and without needing to frequently ship garments overseas. Having the ability to utilize accurate garment measurements fitted onto true-to-life 3D avatars, collections are presented to decision-makers in all different sizes long before they are produced. Although the company has already plunged into the eCommerce world by enabling customers to start to sell with 3D, in the near future they plan to bring an even more personalized buying experience to consumers.

Streamlined fit approval cycles with instant product changes

Reduction of physical resources and transportation costs

Concepts can be visualized for faster decision-making

Provides added flexibility to customers

Removes the dependency on the availability of real-life models

“Utilizing VStitcher’s virtual garments that are true-to-life gives the decision-makers the confidence to depend on the fact that each aspect from the seams and trims through to the garment drapes on the body, will be identical to the physical. Therefore, we can omit any potential errors that may occur further down the line, and adjustments can be made and re-approved within a matter of minutes.”

Kohl’s is a leading Omni Channel retailer with over 1,100 locations across the United States.

Delta Galil began to experiment with Browzwear's 3D apparel design software, VStitcher, to understand how to navigate it for all purposes.

With the guidance of Browzwear's 3D support team, Gokaldas' pattern technicians began training in 3D apparel design software, VStitcher.